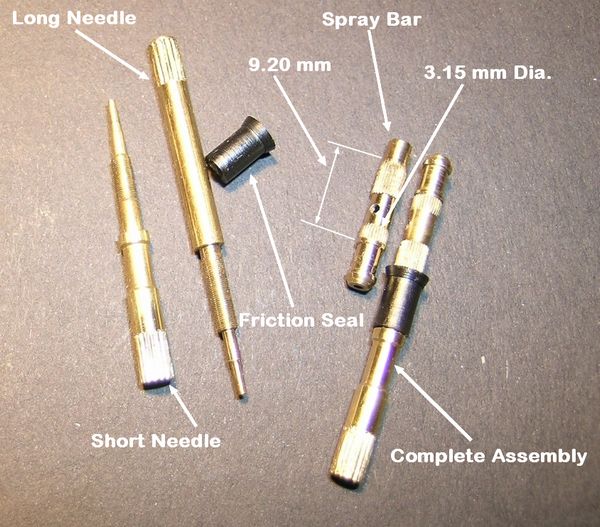

(Parts polished for photo purposes)

PRECISION NEEDLE VALVE FOR USE WITH SMALL ENGINES

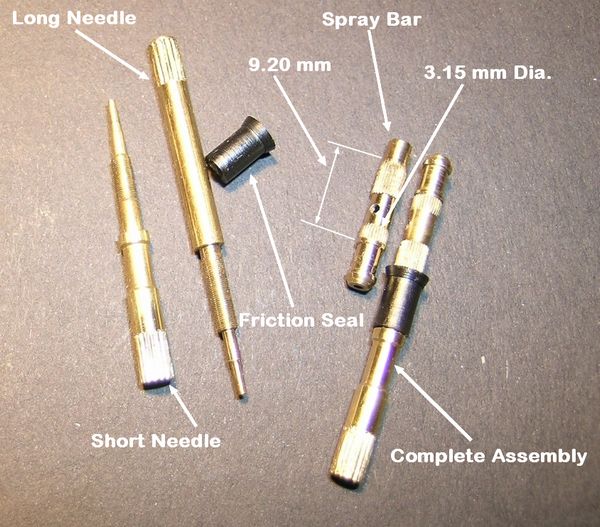

Few small engines have precision needle valves as it is much harder to make the fine threads necessary for this. As a result, adjusting the fuel mixture may be difficult, making it near impossible to achieve the optimum setting. These needles and spray bars have fine threads of 128 per inch. In addition, the needle has a nice taper to make it easy to set and hold the exact setting you want.

Such precision is virtually required if you are running a high pressure fuel feed system such as used in Free Flight. It is most likely you can not run your engine with pressure with the factory needle valve.. This needle and body solves the problem. It is very similar to that used in the high performance needle valve assembly made for the Cox TD /049/.051 engine.

The seal supplied serves two purposes. First, it provides a seal so that the needle setting is not upset with air or fuel leaks. Second, the seal acts as a friction clutch. So, say good bye to the ratcheting click-click needle that is so commonly supplied with factory engines. Because this needle's position is continuously adjustable, you do not have to settle for the "close", second best setting.

This Precision Needle Valve is approved for use with engines used in NFFS Nostalgia events.

You will need to find a way to fix the Spray Bar in your engine. Generally, something like JB Weld will work.

(Parts polished for photo purposes)

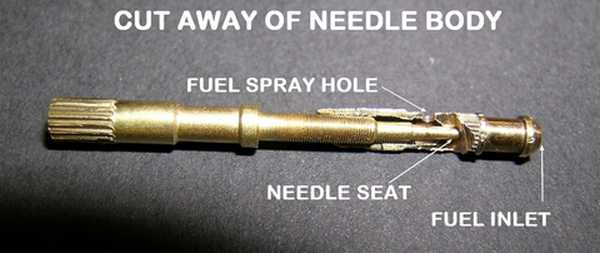

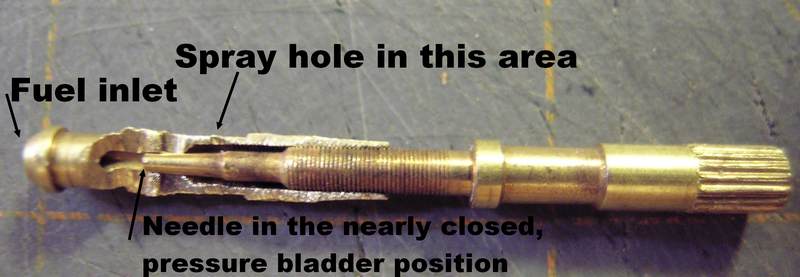

This is what the body looks like in a cutaway showing the needle in place.

This is what the body (spray bar) looks like when put in a Cox Medallion engine.

Al Lidberg describes how he put the body in a Medallion case.

Ok, I've cut off 2 pieces of 5/32" tube to about 3/32" long. Before I cut them on the Harbor Freight tiny cut-off saw, I made a razor saw cut down one side. That wasn't quite enough to get the tubes to collapse enough to slide in so I used a very thin tapered file to enlarge the saw cut. The tubes were pressed in from each side and then the new NV body was placed in there. It's still a loose fit, but now JB Weld will hold it in place. The picture, which came out far better than I thought possible, shows the body in place [upsidedown, for a reason], but a little too far to the left - that tube needs to be a little shorter so the nv body can be centered. The nv body has a raised area on the fuel line end that runs into the tubing. When it is centered, then we'll have to see if those splines still show, in which case they should be filed away before we glue. I'm quite confidentthat this thing will work, however! AL Lidberg: aalmps@aol.com 6-29-07

The OK CUB is also a popular engine for using this retro fit needle valve unit. This shows how Roger La Prelle: r_laprelle@yahoo.com has done his. He used JB Weld to fix it and seal it. Roger reports great results using the needle valve.