BASIC PRESSURE BLADDER INFORMATION

OVERVIEW

We use pressure feed to our competition free flight engines to

better regulate the flow of fuel under the strong accelerations our planes have

when going up. Without a pressure feed (i.e. suction), the engine will have a

tendency to starve for fuel and will have a surging jerky climb. This will

reduce the altitude we reach. Note: for fun or sport flying where the engine and

plane combination does not climb like a rocket, suction is fine and a lot

simpler.

There are two types of fuel pressure used in FF. One uses crankcase pressure fed

to a hard sided tank. This pulsing pressure will add some "push" to the fuel and

aid it in getting to the engine. It is pretty simple to do, and is fairly easy

to do as well as not messy like using bladder feed. But, it does not give the

same forced feed of a bladder and is not commonly used. There is one problem

that does show up when trying to stop the engine. With the line between the

crankcase and the fuel tank, fuel can be sucked back into the crankcase on the

piston up cycle and this can make the engine sputter when you are trying to stop

it by fuel starvation with pinchoff. In these cases, a one-way valve needs to be

added to the crankcase/fuel tank line. A device like our check valve is commonly

used.

Most competition flyers use some sort of bladder to force feed

fuel to the engine. In the past, pen bladders and pacifiers were routinely used,

but these items are scarce today. More common is the use of a thin-walled latex

or neoprene tubing which is inflated with fuel using a syringe. (see below how

for to

make these bladders)

STARTING AN ENGINE ON BLADDER PRESSURE

Under bladder pressure, the fuel comes out like a fire hose.

The way to start an engine is to have the needle pre set. You almost never touch it,

other than maybe a tiny tweak depending on the weather or fuel.

You put the battery on the plug, pinch the fuel line with your finger, release

the clamp you have on the fuel line, get the starter in hand, give the fuel

line a short blip to prime the engine, and hit it with the starter. The engine

should fire immediately, and as it gets going good, release your finger on the

fuel line. Be ready to pinch it if the engine is loading up.

For the initial needle setting on a new engine, I close off the needle

totally. and crack the needle enough to let fuel start to drip out of the

line. I watch for the initial bubbles to start to flow in the line, and stop

the flow by pinching off the line when the fuel reaches the engine inlet. This

will get you in the ball park, on the lean side. With experience, you can tell

by the sound if it is rich or lean. There is a fine difference between rich

and lean needle

settings. It is better to be lean than rich as you can flood it real fast.

Best if you do all this fussing around on a bench rather than in the plane.

When you have the needle setting where the engine screams, leave it alone.

Then put it in a plane and go fly. You may have to give it a tiny tweak, but

that is it.

I used to start .40 size engines by hand, but no more. I stand behind the

plane with the starter on a stooge and push the engine into the starter. I did

hand start a .19 a couple weeks ago for a neighbor kid who could not get it to

run. But, it was in a waist high engine test mount so it was firm and I could

back away fast.

MAKING PRESSURE BLADDERS

The tubing will expand like a fat hot dog or Polish sausage. One

end of the tubing can be tied with a knot, or a one-way check valve can be used.

The advantage of the valve is it allows fuel to be added without removing the

fuel line from the engine and opening up the timer. Care needs to be taken to

avoid losing the rather costly valve in the event of a bladder rupture. Yes,

they frequently burst. The other end of the tubing is mated with a fitting to

match up to the fuel line. The tubing will expand first from the end that is

stretched over the fitting and "grow" rearwards as more fuel is added. The

longer the tubing, the greater the amount of fuel. You will be surprised how

much fuel will go into a short length of tubing. The tubing will yield a

pressure that is quite constant all the way down to nearly empty. Yes, we sell

all of these items.

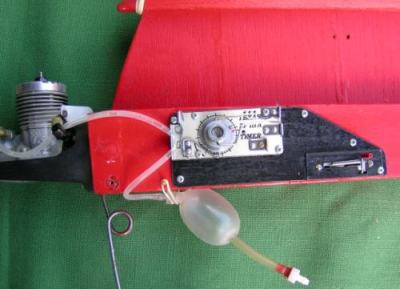

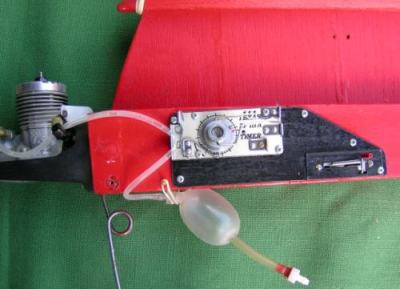

Sometimes the bladder is suspended below the plane and other

times, it is put inside the fuselage where an epoxy sealed cavity has been

built. This is mostly the flyer's choice or preference. The way I do it on most

planes is shown in the photo below. I put a dowel through the fuselage and a

piece of 1/64 ply under the fuselage. Then string a rubber band back and forth

between the dowel ends, trapping the bladder fitting under it. This is very

secure, and yet easy to replace. Ideally, the bladder is at the CG location so

fuel load does not upset the the flight characteristics, but this is not always

feasible. For purposes of the photos, I used air in the bladders, but they fill

up the same with fuel.