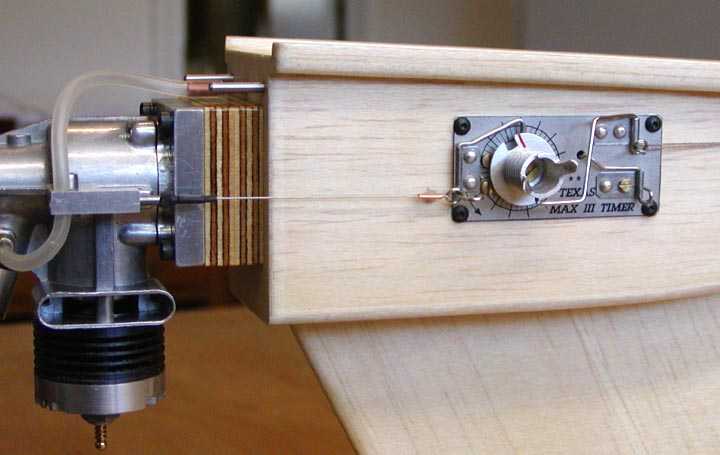

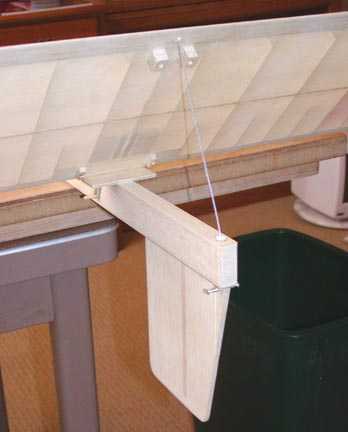

Note how two pegs are used to route the line from the pod mounted timer to be in line with the fuselage

A CLEVER WAY TO DT A HIGH THRUST LINE MODEL

Tandy Walker of Arlington, TX is known as a Master Model Builder. One of his latest projects is a Class A 500 SI T-Bird with an OS .19. Tandy has graciously shared some photos of how he does his DT system. Almost everyone will get an idea they can use out of this. Questions should be directed to Tandy.

Note how two pegs are used to route the line from the pod mounted timer to be in

line with the fuselage

Tandy has used a hard tank in the pod that is pressurized by the engine

crankcase.

The plane came out tail heavy and he needed to shim out the motor to get the

proper CG.

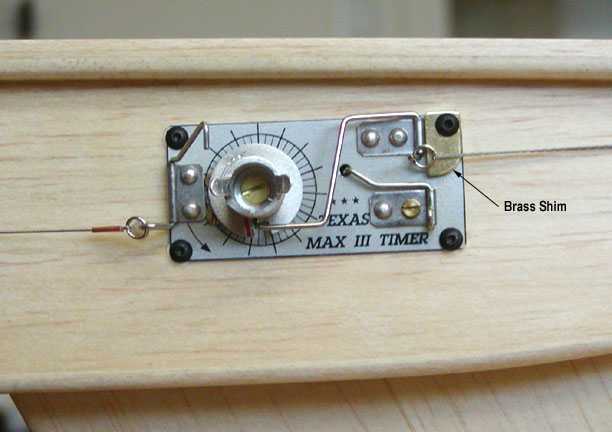

This is a later change to add the shim at the DT post to prevent the split ring

from sliding too low. An important thing to do.

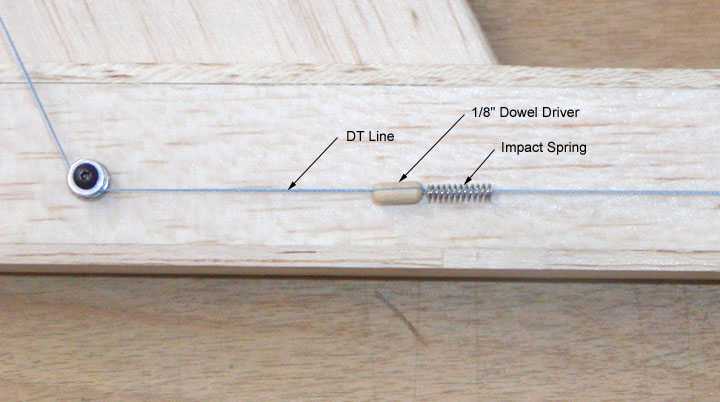

The DT line is routed inside the fuselage back to the rear end. The line limit

stop is to the left of where the

line enters the fuselage.

This is a close up how he limits the line travel to set the stab at 45 degrees

for DT. The dowel is the limit and the spring takes

up the shock of it striking the stop.

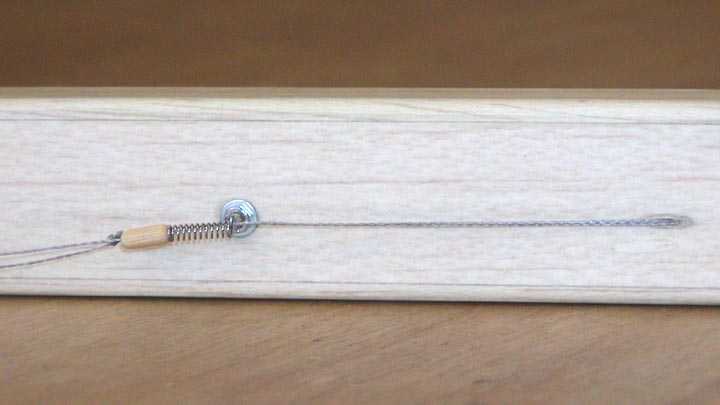

This shows how the dowel, spring, and stop work together to control how far the

stab will lift at DT.

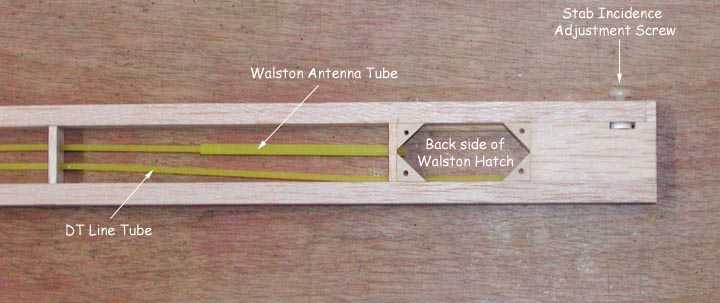

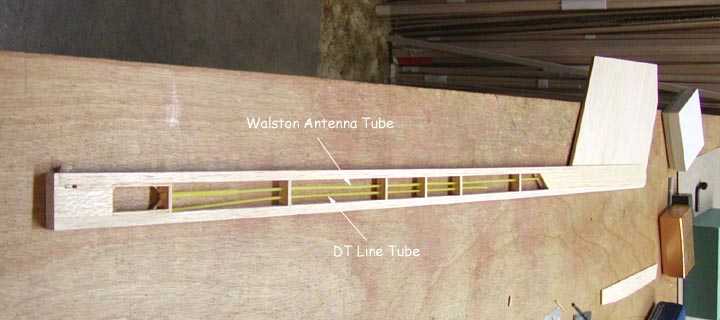

This shows how Tandy routed the DT tube inside the fuselage at the tail. The

line going up goes to the stab.

More detail of the tail end. I would definitely not suggest the Walston

transmitter be located here as it tends to make the plane tail heavy.

This gives you the overall of the fuselage with DT line Tube routing.

This

shows the working tail end. The DT line is routed inside the fuselage inside

some tubing. The line comes up through a hole drilled in a nylon screw that is

used for fine adjustment of stab incidence. Note the use of front and rear keys

to hold the stab in proper alignment when pulled done on the stab platform.

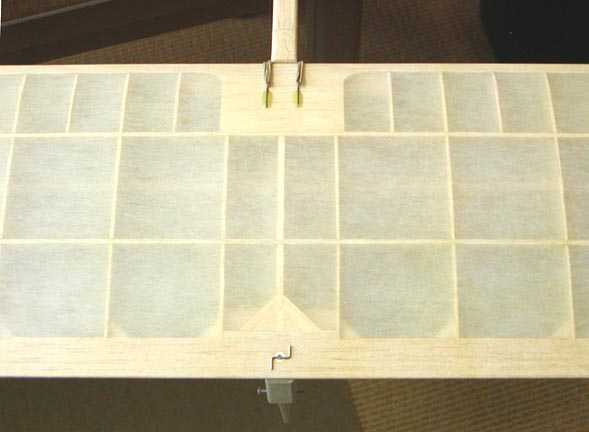

This

shows the working tail end. The DT line is routed inside the fuselage inside

some tubing. The line comes up through a hole drilled in a nylon screw that is

used for fine adjustment of stab incidence. Note the use of front and rear keys

to hold the stab in proper alignment when pulled done on the stab platform.

This

is the stab in the pulled down power and glide position. The double bent piece

of wire is used to retain the DT line. Notice that for transport, the wire will

slip through the trailing edge so the stab can be removed from the plane.

This

is the stab in the pulled down power and glide position. The double bent piece

of wire is used to retain the DT line. Notice that for transport, the wire will

slip through the trailing edge so the stab can be removed from the plane.