USING THE MAX A TIMER IN A HIGH THRUST LINE

MODEL

Use of any dual or multi- function timer in a high thrust line

model presents a problem because the timer can not be "in line" with both the

engine and stabilizer at the same time. Mostly it is a situation of what to do

with the DT line. Larry Davidson of Moneta, VA has solved this quite neatly and

efficiently. In this case, use of the MAX IIIA timer eliminates the need for a

separate remote cutoff device for the fuel line. The same general methods could

be used in any high thrust model. See the Helpful Hints for different modeler's

solution.

This is the completed 585 square-inch T-Bird with the MAX A timer mounted

on the engine pod. The DT line is non-stretch filament and tension is provided

by a simple spring. The spring serves as the stop where it hits the aluminum

tube going down inside the pod and pylon.

This shows how the DT line is routed down inside the pylon.

This shows the completed DT line where it will connect to the

TE of the stabilizer. Note, the nylon screw is used to set decalage.

This shows the layout of the major components in the pod and pylon. The Walston

RF tracker is also shown.

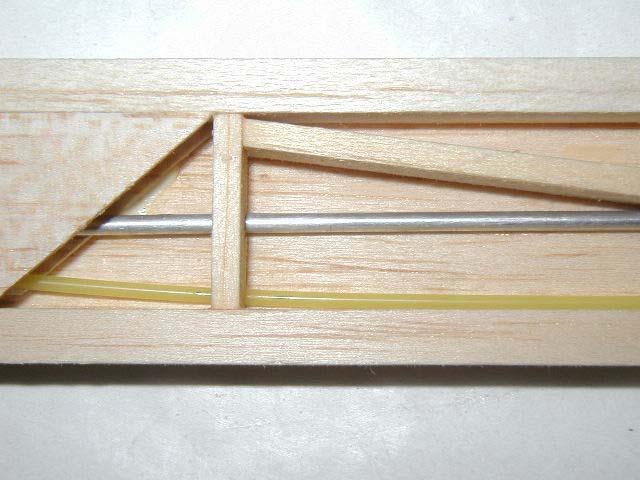

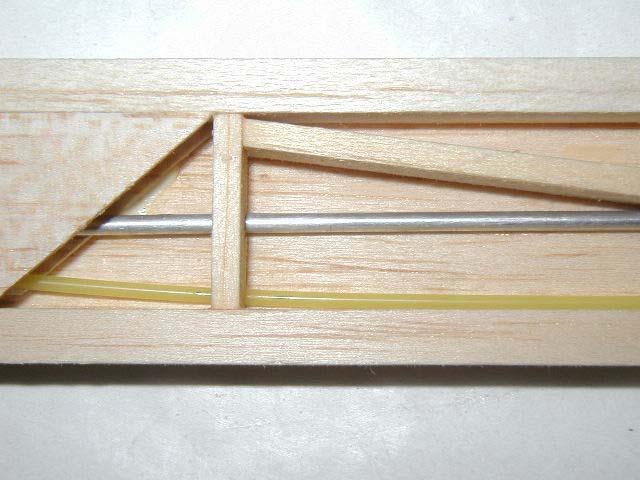

A closer look at how the Aluminum guide tubing for the DT line is shaped.

The DT line is routed inside the small aluminum tubing. The

plastic tubing is for the antenna for the radio tracker, which also installs in

the engine pod on top of the pylon.

The tail end of the DT line showing how the aluminum tubing is

formed to guide the line up to the TE of the stabilizer.

Return to the MAX A Specification and Order Page

Return to the 3F A Specification and Order Page

Return to Helpful Hints